Reflective Embossed Aluminum Sheet

Nov-20-2025

Reflective embossed aluminum sheet is a type of aluminum sheet processed with special techniques, possessing excellent reflective properties and decorative effects. It is widely used in lighting equipment, lamps, and architectural decoration.

Common textures for reflective embossed aluminum sheets include hammered, bean-like, orange-peel, and worm-like patterns:

- Hammered texture:

Formed through mechanical pressing, it features natural and dynamic patterns and a strong three-dimensional effect. Its surface has a distinct unevenness, enhancing the diffuse reflection of light. In the lighting field, it is often used in scenarios requiring soft light, such as plant supplement lamp shades and indoor decorative lighting fixtures.

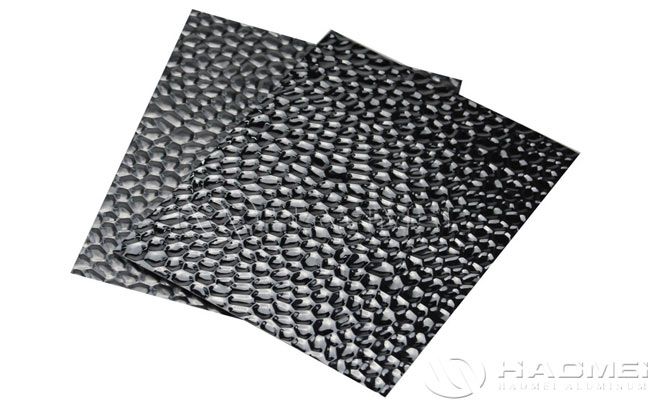

- Bean-like texture:

The texture is distributed in a granular pattern, resembling the arrangement of beans. It can evenly disperse light and reduce glare. It is widely used in lamp reflectors, solar collectors, and other fields.

- Orange-peel texture:

The surface presents a fine unevenness similar to orange peel, with a rough touch but a soft visual appearance. Its diffuse reflection properties optimize light distribution, making it suitable for scenarios requiring uniform lighting, such as shopping mall ceilings and office lighting.

- Insect pattern:

The pattern mimics the texture of insect bodies, creating a unique visual effect. It is commonly used in decorative lighting or personalized lamp designs.

Core advantages of reflective embossed aluminum sheets:

- High luminous efficiency enhancement:

Through mirror reflection or diffuse reflection design, reflective embossed aluminum sheets can significantly improve lighting efficiency. For example, when mirror embossed aluminum sheets are used as reflective materials for lamps, luminous efficiency can be enhanced by more than 60%, effectively reducing light scattering waste and lowering energy consumption. In the field of solar thermal collection, its high reflectivity (up to 95% in some products) optimizes light energy utilization and improves heat collection efficiency.

- Durability and stability:

Aluminum sheets themselves possess corrosion resistance and oxidation resistance, maintaining stable performance over long periods in high-temperature or harsh environments (such as outdoor lighting and industrial plants). Its excellent fire resistance allows a char layer to quickly form on the surface upon contact with fire, preventing the spread of flames and ensuring safety.

- Lightweight and easy to process:

Low density (approximately 2.7g/cm³), lightweight for the same area, facilitating installation and transportation. Supports various processing methods such as embossing, cutting, bending, and stamping, and can be customized with complex textures (such as orange peel texture and diamond texture) to meet personalized design needs.

- Environmentally friendly and economical:

Aluminum has a high recyclability rate, meeting green building standards. Its lifespan is 3-5 times that of iron plates, resulting in lower long-term operating costs, making it particularly suitable for scenarios requiring frequent replacement or maintenance.

Typical application scenarios of reflective embossed aluminum sheets:

- Commercial and industrial lighting

Lamp reflectors: As reflectors for fluorescent lamps and LED lights, they reduce light scattering in non-use areas through focused reflection, improving the brightness of the effectively covered area. Examples include road traffic signs and reflective light troughs in shopping mall ceilings.

High-power LED lighting: High reflectivity (>90%) 5xxx series mirror aluminum plates can replace imported materials, meeting the stringent luminous efficiency requirements of solar equipment and the LED industry.

- Architectural decorative lighting

Interior decoration: Used for ceiling and wall decoration, using mirror reflection to expand the sense of space and create a dreamlike effect. For example, ceiling designs in public spaces such as hotels and subway stations.

Building curtain walls: Combining embossed textures and reflective properties to enhance the modernity and energy efficiency of building appearance.

- Special environment lighting

Outdoor lighting: Corrosion-resistant and weather-resistant aluminum plates are suitable for streetlights and landscape lighting, maintaining performance even after long-term exposure to wind and rain.

Explosion-proof lighting: In flammable and explosive environments such as chemical plants and wind power platforms, the fire-resistant and explosion-proof properties of aluminum plates ensure safety.

Technical parameters and selection recommendations

- Reflectivity

General decorative applications: Select 1xxx or 3xxx series aluminum sheets with a reflectivity ≥80%.

High performance lighting: Prioritize 5xxx series mirror aluminum sheets with a reflectivity ≥95% to meet the needs of the LED and solar energy industries.

- Thickness and specifications

Lamp reflectors: Commonly used coils with a thickness of 0.2-0.8mm and a width of 1250mm, facilitating stamping and forming.

Building curtain walls: Medium-thick plates (6.0-25.0mm) or thick plates (25-200mm) are selected according to design requirements to ensure structural strength.

- Surface treatment

Mirror aluminum sheets: High surface smoothness and excellent reflective effect, suitable for scenarios requiring high-precision light control.

Embossed aluminum sheets: Achieve diffuse reflection through texture design, reducing glare, suitable for environments requiring soft lighting (such as conference rooms and hospitals).