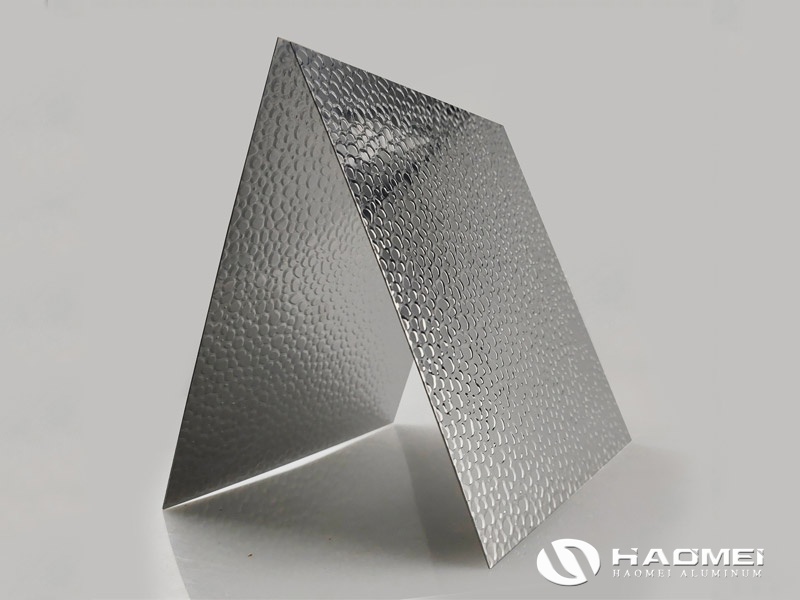

Aluminum Hammered Pattern Sheet

Feb-05-2026

Aluminum hammered pattern sheet is a practical embossed aluminum product used when designers and fabricators need a decorative surface that also hides scratches, fingerprints, and minor handling marks. From an export buyer's perspective, the real value is consistency: a stable pattern, repeatable gloss, and predictable formability across batches so downstream processes like bending, stamping, and lamination run without surprises.

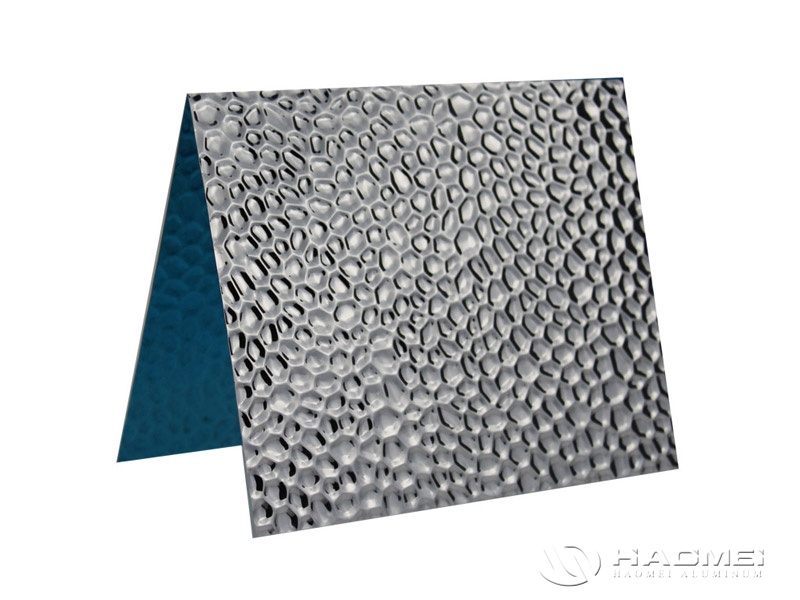

An aluminum hammered pattern sheet is an aluminum coil or sheet that has been mechanically embossed with a "hammered" texture. The pattern can look hand-beaten, pebbled, or hammertone depending on the embossing roll design and process settings.

It is different from:

Chequered/tread plate: primarily anti-slip, deeper raised bars.

Stucco embossed: typically orange-peel style used in insulation jacketing and refrigeration; hammered textures may be finer or more decorative.

Textured paint only: a coating can mimic texture, but a true aluminum hammered pattern sheet has physical emboss depth, affecting rigidity and light diffusion.

For procurement, clarify whether the supplier is offering true embossed metal or a paint texture, because thickness tolerance, bending radius, and surface repairability differ.

When importing aluminum hammered pattern sheet, the best outcomes come from specifying a small set of critical parameters rather than only "hammered finish."

Alloy choice affects formability, corrosion resistance, and flatness after embossing.

Common selections:

1xxx (1050/1060/1070, H14/H24): excellent corrosion resistance and high reflectivity; popular for lighting reflectors and decorative panels.

3xxx (3003, H14/H24): strong general-purpose option; good for deep bending and architectural use.

5xxx (5052, H32): higher strength and marine resistance; used in harsher environments but may cost more.

Temper guidance:

Choose H14/H24 when moderate forming is needed.

Choose O temper if tight radii or more aggressive forming is expected, then confirm emboss retention after forming.

For hammered aluminum sheet, thickness is usually specified as base metal thickness (BMT). Embossing increases apparent stiffness but can also introduce residual stress if poorly controlled.

Typical procurement ranges:

0.3–1.2 mm: lighting, appliance skins, interior cladding.

1.5–3.0 mm: protective panels, transport interiors, heavy-duty decorative parts.

Ask suppliers to declare:

Emboss depth (peak-to-valley), or at least a reference sample.

Pattern repeat size and directionality (important for large façade or panel alignment).

An aluminum hammered pattern sheet can be supplied as mill finish, anodized, or coated (PE/PVDF) depending on end use.

Practical notes:

For anodizing, surface cleanliness and uniform rolling/embossing are essential to avoid shade variation.

For coil coating, request coating system details (primer + topcoat thickness) and verify bend/T-bend performance on embossed surfaces.

For food-adjacent applications (certain decorative trims), confirm compliance needs and cleaning requirements.

Engineers and product teams choose aluminum hammered pattern sheet for three reasons: optics, durability perception, and processing efficiency.

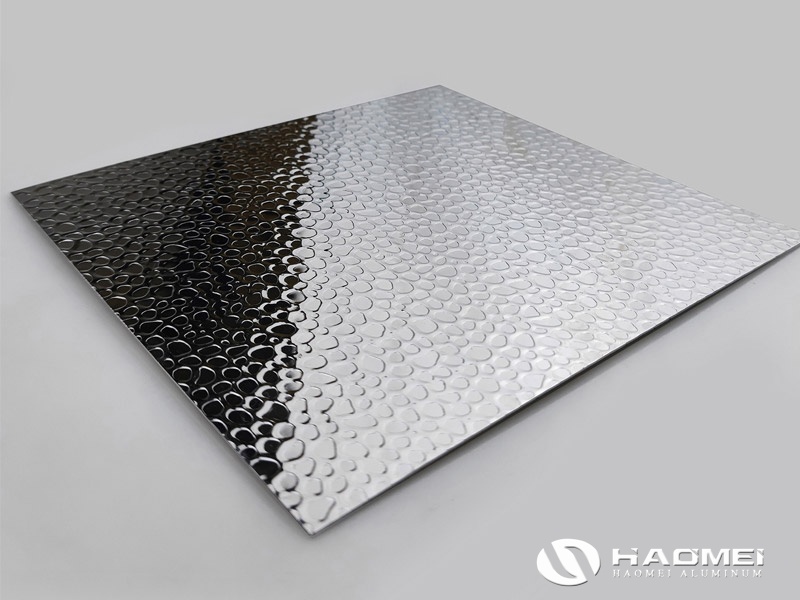

Scratch and dent masking: the hammered texture diffuses reflections, making small defects less visible than on flat sheet.

Improved perceived value: textured metal reads as "premium" without needing heavy gauge.

Light diffusion and glare control: in luminaires and reflectors, the texture can reduce glare while keeping high reflectance (especially with high-purity alloys).

The texture also adds a small amount of stiffness, which can help with oil-canning control in thin-gauge panels, though embossing quality and leveling are decisive.

A single aluminum hammered pattern sheet specification rarely fits all markets. Below are typical use cases and what to prioritize.

For architectural use, aluminum hammered pattern sheet should be specified with consistent gloss and color control if coated, plus a stable pattern alignment.

Prefer 3003 H24 or 5052 H32 depending on environment.

If used outdoors, specify PVDF or equivalent durable coating.

Ask for salt spray and UV performance where relevant.

Reflector performance is sensitive to surface cleanliness and reflectivity.

Use 1050/1060/1070 for high reflectance.

Confirm whether the aluminum hammered pattern sheet is supplied with protective film suitable for laser cutting or punching.

Validate diffusion behavior with photometric testing when necessary.

Here, consistency and scratch masking are key.

Specify film type (blue film, clear film) and adhesion level to avoid residue.

Confirm compatibility with adhesives or laminates.

Request tight control over flatness to prevent waviness after fabrication.

Many claims sound similar across suppliers, so buyers should ask for measurable controls.

Key QC items:

Thickness tolerance (by micrometer across width) and coil profile.

Emboss uniformity: pattern depth consistency, no roll marks, no "ghosting."

Surface defects: black spots, oil stains, scratches, chatter.

Mechanical properties: yield/tensile/elongation aligned with alloy-temper standard.

Coating inspection (if coated): dry film thickness, gloss, adhesion (cross-hatch), MEK rub, bend test.

Practical export tip: request pre-shipment photos and short videos showing surface under angled light. Hammered textures can look acceptable in diffuse lighting but reveal roll marks under specular inspection.

A well-made aluminum hammered pattern sheet is generally easy to process, but textured surfaces change a few shop-floor assumptions.

Cutting: shearing is common; for laser cutting, confirm coating and film behavior to avoid edge contamination.

Bending: specify bend direction relative to pattern if aesthetics matter. Use larger bend radii for higher tempers.

Welding: texture can trap contaminants; clean thoroughly. For decorative panels, consider mechanical fastening to preserve appearance.

Adhesives/lamination: emboss can reduce contact area; use appropriate adhesive systems and test peel strength.

If the part will be post-painted, note that emboss depth can increase paint consumption and influence gloss.

Disputes on aluminum hammered pattern sheet often come from subjective expectations. A strong purchase spec includes reference samples and measurable targets.

Recommended items to include:

Alloy/temper standard (ASTM/EN/GB equivalent).

BMT thickness and tolerance.

Sheet/coil width, length, and ID/OD for coils.

Pattern name or roll code, plus a physical sample or high-resolution reference.

Surface finish: mill finish, anodized, PE, PVDF, with film requirement.

Application statement (reflector, cladding, trim) so the supplier can align process controls.

Inspection method and acceptance criteria: lighting angle, distance, allowable defects.

For container planning, confirm whether the aluminum hammered pattern sheet is supplied as sheets on pallets or coils with eye-to-wall/eye-to-sky orientation.

Because an aluminum hammered pattern sheet is valued for its appearance, transit protection is not optional.

Best practices:

Moisture control: desiccant and sealed wrapping to reduce oxidation/water staining.

Edge protection: corner guards and hard boards.

Film protection: specify film thickness and peelability.

Pallet standards: fumigated wood where required, or plywood/steel pallets.

Ask for packing photos before shipment, and confirm labeling includes coil number, net/gross weight, alloy-temper, and production date for traceability.

Global buyers are increasingly optimizing total cost of ownership rather than only FOB price. For aluminum hammered pattern sheet, that means:

Lower rejection rates through consistent emboss rolls and stable annealing.

Better forming yield with the correct temper selection.

Faster installation due to scratch-masking surfaces and reduced rework.

Stable availability as construction and appliance cycles fluctuate.

Distributors often prefer suppliers who can provide multiple patterns (hammered, stucco, linen) with consistent alloy and coating platforms, simplifying inventory while serving different customer segments.

Before placing a large order of aluminum hammered pattern sheet, run a short validation plan:

Visual check under strong angled light for roll marks and gloss inconsistency.

Bend test to the intended radius; inspect for coating cracks (if coated) and pattern distortion.

Measure thickness across width and along length.

If used as a reflector, test reflectance/diffusion with your lab or a third party.

Verify film removal after storage (peel test after heat exposure if your process includes ovens).

A disciplined sample review is usually the most cost-effective way to ensure the aluminum hammered pattern sheet you import behaves predictably in mass production and installation.