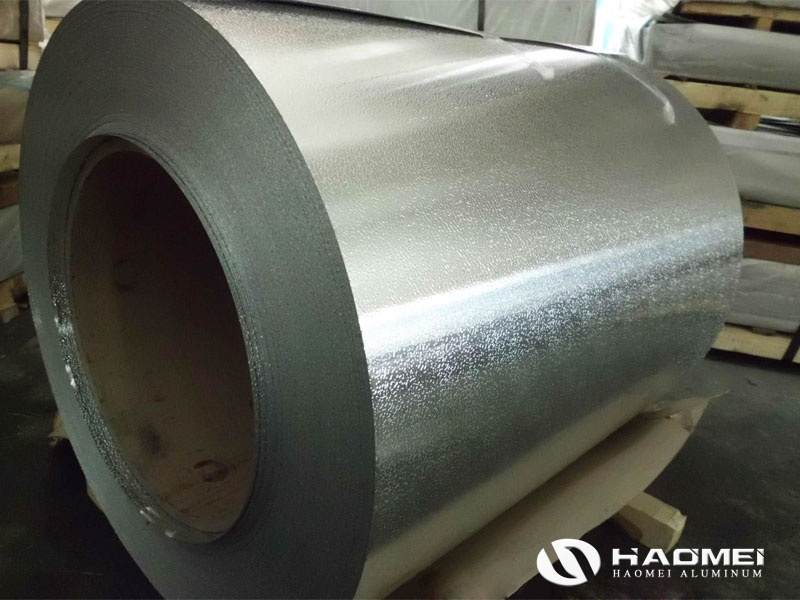

Embossed Aluminum Sheet Supplier China

Feb-13-2026

Selecting an embossed aluminum sheet supplier China is not only a price decision. In day-to-day export production, I have seen that stable emboss depth, coating consistency, and packing discipline decide whether customers get smooth forming, clean appearance, and low after-sales risk. Stucco embossed aluminum (also called orange peel or pebble emboss) is popular because it upgrades surface durability and hides minor handling marks while keeping aluminum's light weight and corrosion resistance.

Embossed aluminum sheet is made by passing aluminum through patterned rollers that create a repeatable texture. The texture is not just cosmetic. It increases surface rigidity slightly, reduces glare, improves scratch masking, and can support adhesive bonding or lamination when paired with the right coating system.

From a technical perspective, the key to good stucco embossed material is repeatability: the pattern must be uniform across width, from head to tail of coil, and from coil to coil. Any uncontrolled roller wear or unstable tension shows up as pattern distortion, uneven gloss, or "shadow lines" after forming.

When you evaluate a supplier, ask for a complete spec set. These are the parameters that affect processing and final performance.

Common alloys for stucco embossed aluminum sheet/coil include:

1xxx series (e.g., 1050, 1060, 1100): excellent formability and thermal conductivity, often used for insulation jacketing and decorative panels.

3xxx series (e.g., 3003, 3105): stronger than 1xxx, very common for insulation cladding, roofing trims, and general industrial covers.

5xxx series (e.g., 5052): higher strength and better marine corrosion resistance, used where durability is critical.

Typical tempers:

O: maximum formability (deep bending, complex shaping).

H14/H24: balanced strength and formability (common export standard).

H16/H18: higher hardness, better dent resistance, less forming margin.

In practical export work, mismatch of temper is one of the most common causes of customer complaints (cracking during bending or insufficient stiffness). A reliable supplier will recommend temper based on your forming radius and end-use.

Typical ranges seen in global demand:

Thickness: 0.2 mm to 3.0 mm (0.3-1.2 mm is especially common for jacketing and appliance panels)

Width: 600-1250 mm typical; wider is possible with capable mills

Length: sheets cut to size, or supplied as coil for roll-forming/lamination

For coils, also confirm inside diameter (ID) and maximum outer diameter (OD) that matches your decoiler. Many shipping issues come from coils that do not fit the customer's line.

Popular patterns:

Stucco/orange peel: the mainstream choice for insulation jacketing and appliance liners

Diamond: more decorative and anti-slip

Request:

pattern type and repeat

emboss depth tolerance

surface uniformity standard

A strong supplier controls roller condition and tension to avoid "flat areas" or over-embossed zones.

Options include:

Mill finish embossed: economical, used where coating is not required

Anodized: improved corrosion resistance and appearance

Painted (PE/PVDF): for outdoor exposure and branding colors

Film-laminated: extra scratch resistance for appliances or panels

For painted embossed products, coating quality matters as much as the aluminum. Confirm:

coating type (PE vs PVDF)

coating thickness (primer + topcoat)

gloss range and color tolerance

adhesion (cross-hatch), impact, and bend performance

From production and customer feedback, these benefits consistently show value:

Scratch masking and better handling toleranceEmbossing hides minor scuffs that would be obvious on flat sheet. This reduces rejection rates during fabrication and installation.

Improved perceived quality at low added weightThe texture makes panels look more premium while keeping aluminum's lightweight advantage.

Good corrosion resistance with the right alloy/coating3xxx and 5xxx alloys already perform well, and coating systems can extend life outdoors or in coastal areas.

Process-friendly for roll forming and claddingEmbossed coil feeds well into common forming and lamination processes when thickness and temper are selected correctly.

Thermal performance support for insulation systemsFor pipe and HVAC insulation jacketing, aluminum's corrosion resistance and the embossed surface's durability make it a dependable outer layer.

A technically capable embossed aluminum sheet supplier China typically serves these scenarios:

Stucco embossed 1060/3003 in H14/H24 is widely used for industrial insulation cladding. Buyers care about coil flatness, consistent emboss, and clean oil control because it affects onsite appearance.

Refrigerator backing panels, liners, and decorative covers benefit from scratch masking and cleanability. Here, the critical points are coating adhesion, color stability, and packing protection.

Painted embossed sheets offer durability and design flexibility. For outdoor use, PVDF coatings and controlled color tolerance are key.

Embossed aluminum is used for protective panels where dent resistance and a "non-flat" visual finish are preferred.

If you want consistent shipments, these checkpoints save time:

Ask for full inspection items: thickness tolerance, width tolerance, coating thickness, gloss, color delta, emboss depth, and surface defect criteria.

Confirm packaging standard: moisture barrier, edge protectors, wooden pallets, and coil eye orientation. Export packing is not optional; it is part of the product quality.

Request traceability: heat number, coil number, and inspection report per batch.

Sample approval with your process: test bending radius, roll-forming, adhesive bonding, and salt spray if needed.

If your website includes technical pages for buyers, add internal links where they naturally fit, such as stucco embossed aluminum coil, embossed aluminum sheet, or embossed aluminum sheet manufacturer to guide visitors into deeper specifications and available stock.