Stucco Embossed Aluminum 3003-H14

Feb-10-2026

Stucco embossed aluminum 3003-H14 is increasingly specified where manufacturers want a balance of durability, appearance stability, and fast processing. While smooth sheet is still common, the industry shift toward textured surfaces reflects a practical reality: in real-world logistics and jobsite handling, minor contact marks and waviness are unavoidable. A controlled embossed pattern helps mask those imperfections, delivering a consistent look across long production runs and varied installation conditions.

Alloy 3003 is an Al-Mn series material known for strong general corrosion resistance and dependable formability. The H14 temper provides a half-hard condition that sits in a useful middle ground: stiff enough to hold shape for jacketing and panel work, while still accommodating forming operations such as rolling, bending, and profiling without becoming overly brittle.

That balance matters in high-throughput environments. Many insulation and ductwork fabricators run a mix of coil-fed lines and brake-formed parts, often within the same facility. 3003-H14's stable workability reduces the need for frequent parameter changes, helping keep edge quality and bend consistency under control.

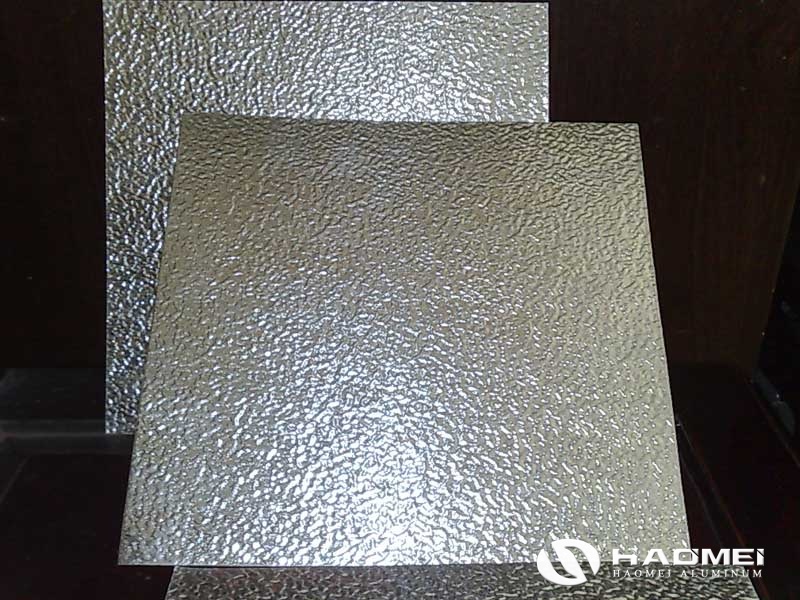

Stucco embossing is more than a cosmetic texture. The pattern is produced through precision-engraved rolls, designed to create repeatable peaks and valleys along the surface. When paired with consistent rolling control, the result is a sheet or coil that offers:

Improved dent masking during transport, decoiling, and installation

Higher perceived flatness, especially across wider sheets

Better handling grip, reducing slip on production lines and job sites

One of the most established uses is aluminum jacketing. In many markets, contractors specify aluminum over galvanized steel when corrosion resistance and long-term appearance are priorities. A real-world detail that purchasing teams often recognize: ASTM C1729 is a widely referenced standard for aluminum jacketing used in insulation systems, with common thickness ranges often centered around practical field handling requirements.

For projects involving petrochemical facilities, power plants, LNG-related infrastructure, or commercial chilled-water systems, the typical concerns are water ingress, exterior corrosion, and jobsite abuse. Stucco embossed 3003-H14 is valued here because it remains workable for cutting and forming while delivering a finish that hides scuffs and small dents.

If you are specifying materials for this segment, product configurations like Stucco Embossed Aluminum Jacketing are commonly aligned with contractor expectations on texture, temper, and supply form.

In HVAC manufacturing, surface consistency and throughput matter. Stucco embossed sheet is frequently used for outer facings, casing panels, and formed covers where a clean, uniform appearance is required but mirror-like cosmetics are unnecessary.

A practical manufacturing note: many duct and panel lines rely on consistent coil geometry to avoid tracking issues during roll forming. Stable coil set, controlled thickness tolerance, and predictable surface friction help reduce line stoppages.

Cold-room systems, refrigerated transport assemblies, and insulation-related housings benefit from aluminum's corrosion resistance and low maintenance. The embossed surface improves visual durability in service environments where routine knocks from tools, trolleys, or packaging are expected.

While alloy and temper define the baseline, procurement teams often make final decisions based on repeatability and risk control:

Process consistency: embossing depth uniformity, minimal chatter marks, and stable mechanical behavior in bending

Supply reliability: steady coil-to-coil performance, practical lead times, and export-ready packaging

Quality verification: traceable mill test documentation and inspection practices that match international trade norms

The broader insulation and HVAC supply chain is trending toward materials that reduce total installed cost rather than simply lowering raw material price. Textured aluminum like stucco embossed 3003-H14 fits that direction: it is engineered for field realities, supports efficient fabrication, and maintains a consistent appearance after handling.

For teams sourcing at scale, the key is aligning alloy/temper, emboss pattern, and supply form (sheet or coil) with the true end-use conditions. When those elements are matched correctly, stucco embossed aluminum 3003-H14 becomes a straightforward, low-risk material choice across insulation jacketing, HVAC production, and refrigeration-related applications.