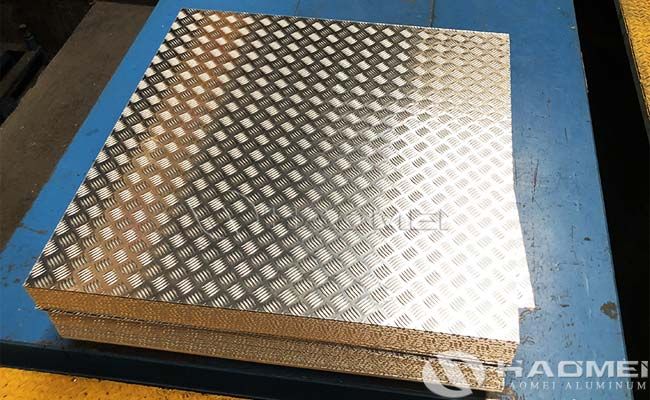

AlMg3 EN AW 5754 H114 Tread Checkered Plate

Jan-15-2026

As the production technology manager at Haomei Aluminum, with over a decade of experience in aluminum tread plate production, I firmly believe that the core value of high-quality aluminium checker plate lies in "precise composition matching + meticulous process control + deep adaptation to various application scenarios." AlMg3 EN AW 5754 H114 tread plate, as our main export product, leverages the inherent advantages of aluminum-magnesium alloys and optimized processing in the H114 temper to become the preferred material for numerous industrial applications.

From a compositional perspective, EN AW 5754 aluminum belongs to the classic Al-Mg alloy system, with magnesium content strictly controlled within the 2.6%-3.6% range. This core ratio is the cornerstone of its performance. Compared to conventional aluminum alloys, this composition endows the sheet with excellent corrosion resistance, especially outstanding tolerance to harsh environments such as seawater and industrially polluted atmospheres. This is a key reason for its widespread application in shipbuilding and marine engineering. Meanwhile, we monitor the content of impurities such as silicon and iron in real time using a spectrometer, ensuring that silicon is ≤0.4% and iron is ≤0.4%, avoiding increased material brittleness caused by impurities and guaranteeing the weldability and processing stability of the sheet metal. Actual test data shows that the strength deviation between the argon arc weld and spot weld and the base material is ≤10%, fully meeting the stringent requirements of welded structural components.

Process control is the guarantee of quality. The achievement of the H114 temper stems from our precise control of the rolling and annealing processes. In production, we employ a complete process system of "homogenization annealing - hot precision rolling - cold rolling embossing - stabilization heat treatment": homogenization annealing at 440℃ for 12 hours ensures a uniform and dense alloy microstructure; the cold rolling embossing stage uses high-precision molds to guarantee a pattern depth deviation of ≤0.2mm, achieving clear textures and stable anti-slip performance (dry friction coefficient ≥0.5, reaching R10 anti-slip level) for both five bar and lentil-shaped patterns; the final stabilization heat treatment precisely balances strength and plasticity, maintaining the finished product's tensile strength at 190-260MPa, yield strength ≥80MPa, and elongation ≥10%, meeting industrial load-bearing requirements while facilitating subsequent bending and stamping processes.

Based on industry experience, the core advantage of AlMg3 EN AW 5754 H114 tread plate lies in its "all-scenario adaptability."

For logistics and transportation scenarios, we recommend the five bar pattern model, with the ribs aligned with the direction of cargo transport to enhance longitudinal load-bearing capacity. The 4-8mm thickness meets the impact resistance requirements of truck bodies and logistics pallets.

For industrial anti-slip applications, the lentil-shaped pattern is more advantageous; 3-6mm thick sheets are suitable for workshop floors and stair treads, effectively reducing the risk of slipping even in humid environments.

In the marine and wind power sectors, its resistance to salt spray corrosion makes it an ideal material for ship decks and spiral staircases in wind turbine towers.

Furthermore, we can customize widths up to 2200mm according to customer needs, coupled with a comprehensive surface inspection system (ultrasonic testing to detect internal defects and eddy current testing to screen for surface microcracks) to ensure that every batch of exported products complies with EN 485 and EN 1386 standards.

In the aluminum tread plate export sector, customers' demands for quality stability and technical services are increasing. Haomei Aluminum consistently adheres to standards of precise composition, refined processes, and comprehensive testing in crafting 5754 H114 aluminum tread plate. We provide customers with high-quality products that meet international standards, and our technical team offers scenario-based selection guidance. We firmly believe that only by deeply integrating technology into customer needs can we maximize product value and application effectiveness.