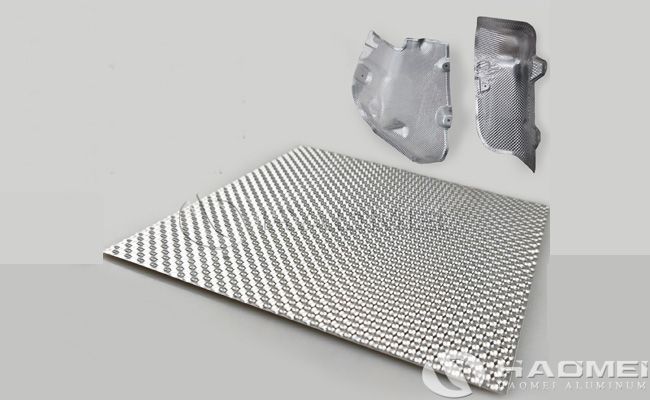

Pearl Spherical Embossed Aluminum Sheet

Aug-22-2025

Pearl spherical embossed aluminum sheet is a sheet with a die-cast pearl spherical pattern on an aluminum or aluminum alloy base. The name comes from the small spherical patterns on the surface, resembling pearls. Its beautiful appearance and unique decorative effect are its name.

Material and Alloy Composition:

In addition to pure aluminum series such as 1050 and 1060, common materials include alloys such as 3003 and 5052. Pure aluminum 1050 and 1060 offer excellent ductility and corrosion resistance, and are relatively affordable. 3003 aluminum alloy is an aluminum-manganese alloy with slightly higher strength than pure aluminum, offering better corrosion resistance and processability. 5052 aluminum alloy is an aluminum-magnesium alloy with high strength and hardness, and excellent corrosion resistance, especially against seawater.

Specifications of Pearl Spherical Embossed Aluminum Sheet:

- Thickness: Generally ranges from 0.15mm to 6.0mm, with a common thickness of 0.2mm to 0.9mm. However, a wider range of thicknesses can be achieved depending on the production process and customer requirements. - Widths: Available in sizes from 300mm to 2200mm, with common widths including 1000mm, 1220mm, and 1500mm. Specific widths can be customized according to customer requirements.

- Length: There is generally no fixed standard and can be cut to meet actual needs. Common lengths include 2000mm, 2440mm, and 3000mm.

Production Process:

Aluminum ingots are first melted and rolled into aluminum slabs of the desired thickness. These slabs are then fed into an embossing machine, where they are pressed under pressure and temperature using a mold with a pearl-shaped pattern, creating a pearl shaped pattern on the aluminum sheet. To enhance corrosion resistance, wear resistance, and decorative properties, the embossed aluminum sheet can undergo surface treatments such as anodizing, painting, and lamination.

Performance Characteristics:

- High Strength:

The unique pearl spherical pattern makes the aluminum sheet stronger than ordinary patterned aluminum sheet. For example, its tensile strength reaches approximately 70MPa, its elongation is around 30%, and it is less susceptible to cracking during stamping and other processes.

- Excellent Corrosion Resistance:

Aluminum itself has excellent corrosion resistance. After surface treatments such as anodizing, a dense oxide film forms on the aluminum sheet, further enhancing its corrosion resistance and resisting environmental erosion such as acid rain and salt spray.

- Excellent Anti-Slip Performance:

The pearl spherical pattern creates a rough surface, increasing friction and providing excellent anti-slip properties. It is suitable for applications requiring anti-slip properties, such as vehicle floors and cold storage floors.

- Excellent Heat Dissipation:

Aluminum has excellent thermal conductivity, and the unique pattern structure of the pearl spherical embossed aluminum sheet increases its surface area, facilitating heat dissipation. It can be used in areas requiring heat dissipation, such as automotive engine compartments and exhaust pipes.

- Processing Performance:

Pearl spherical embossed aluminum sheet, made of pure aluminum and wrought aluminum alloy, can be processed through press forming processes such as stamping, stretching, and deep drawing. It can be formed into various shapes and very thin products to meet the needs of different application scenarios.

Pearl spherical embossed aluminum sheet is primarily used in the automotive industry, such as chassis cooling, engine shields, and exhaust pipe heat shields. It can also be used in the outer packaging of household appliances such as refrigerators and air conditioners, as well as packaging pipes.