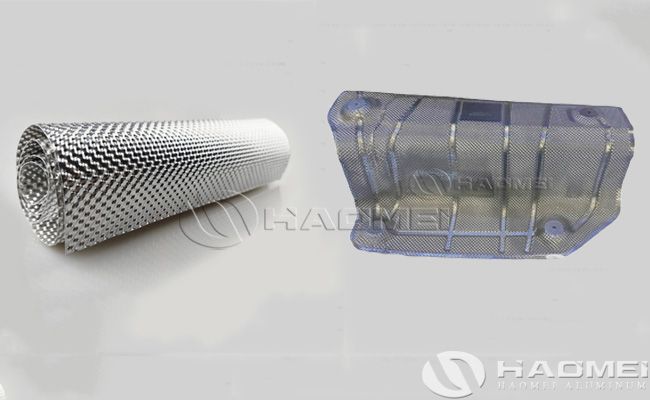

Hemispherical Embossed Aluminum Heat Shield Sheet

Nov-13-2025

Hemispherical embossed aluminum heat shield sheet is an aluminum sheet with a hemispherical embossed texture on its surface. It combines heat insulation, decoration and structural reinforcement functions, and is widely used in automotive engines, exhaust pipe insulation, industrial protection and architectural decoration.

Material and alloy of hemispherical embossed aluminum heat shield sheet:

Hemispherical embossed aluminum sheet typically uses aluminum alloys such as 1050, 1060, 3003, and 5052 as the base material. Specifically:

1050/1060: Pure aluminum series, excellent electrical and thermal conductivity, strong corrosion resistance, suitable for applications requiring heat dissipation such as automotive exhaust pipe covers.

3003: Aluminum-manganese alloy, outstanding rust resistance, slightly higher strength than pure aluminum, commonly used in humid environments such as cold storage floors and truck compartments.

5052: Aluminum-magnesium alloy, excellent corrosion resistance, suitable for highly corrosive environments such as marine or chemical plants.

Performance advantages of hemispherical embossed aluminum heat shield sheet:

- Heat insulation performance

The hemispherical embossed structure increases surface area, improving heat reflection and heat dissipation efficiency. Meanwhile, aluminum itself has a low thermal conductivity (approximately 237 W/m·K), effectively blocking heat transfer and making it suitable for heat insulation protection of high-temperature components such as engine compartments and exhaust pipes.

- Physical properties

Thickness range: 0.2mm-1.0mm (common specifications), meeting the strength requirements of different scenarios.

Tensile strength: 1050 aluminum material has a tensile strength of approximately 50-80MPa and an elongation of 30%, making it less prone to cracking during stamping.

Surface treatment: Anodizing enhances wear resistance and corrosion resistance, while also allowing for color customization.

Production process of hemispherical embossed aluminum heat shield sheet:

- Embossing process:

A hemispherical embossed texture is formed on the surface of the aluminum sheet using high-pressure roller pressing equipment.

Key parameters include:

Roller Diameter: 500mm, ensuring uniform pattern.

Motor Power: 15kW variable frequency speed control motor, paired with a 400 horizontal reducer, achieving precise pressure control.

Flatness: The processed sheet has extremely high flatness, facilitating stamping feeding.

- Quality Standards

The product conforms to national standard, requiring no burrs or sharp edges, a pressing density of 156±17 pieces/cm², and a pressing height of 2±0.05mm to ensure the density and strength of the stamped product.

Application scenarios of hemispherical embossed aluminum heat shield sheet:

- Automotive sector

Engine heat insulation panels: Double-sided hemispherical embossed aluminum sheets effectively reflect engine heat, protecting surrounding components.

Exhaust pipe protective covers: Single/double-sided embossed designs combine heat insulation and anti-slip functions, widely used in FAW-Audi and other models.

Radiator heat insulation covers: Hemispherical structures improve heat dissipation efficiency and extend the service life of radiators.

- Industrial protection

Chemical pipelines: Corrosion-resistant aluminum materials combined with embossed surfaces prevent pipe slippage due to thermal expansion and contraction.

Wind power platforms: Anti-slip plates require a high coefficient of friction; hemispherical patterns meet this requirement.

- Architectural decoration

Exterior curtain walls: Embossed aluminum sheets combine decorative and functional properties, reducing light pollution.

Interior ceiling: Hemispherical textures disperse sound waves, improving the acoustics of the space.

Selection considerations of hemispherical embossed aluminum heat shield sheet:

Scenario matching: 1050/1060 is preferred for high-temperature environments, 3003 for humid environments, and 5052 for highly corrosive environments.

Thickness selection: Stamped parts commonly use 0.4mm-1.0mm; structural parts require calculation based on load.

Surface treatment: Anodizing improves weather resistance and is suitable for outdoor applications.

With the development of lightweight automobiles and new energy vehicles, the demand for hemispherical embossed aluminum heat shield sheets continues to grow. Double sided embossed designs are gradually replacing single-sided products due to their higher heat dissipation efficiency. Simultaneously, suppliers are improving production efficiency and reducing costs by optimizing embossing equipment (such as using CNC roller pressing technology).